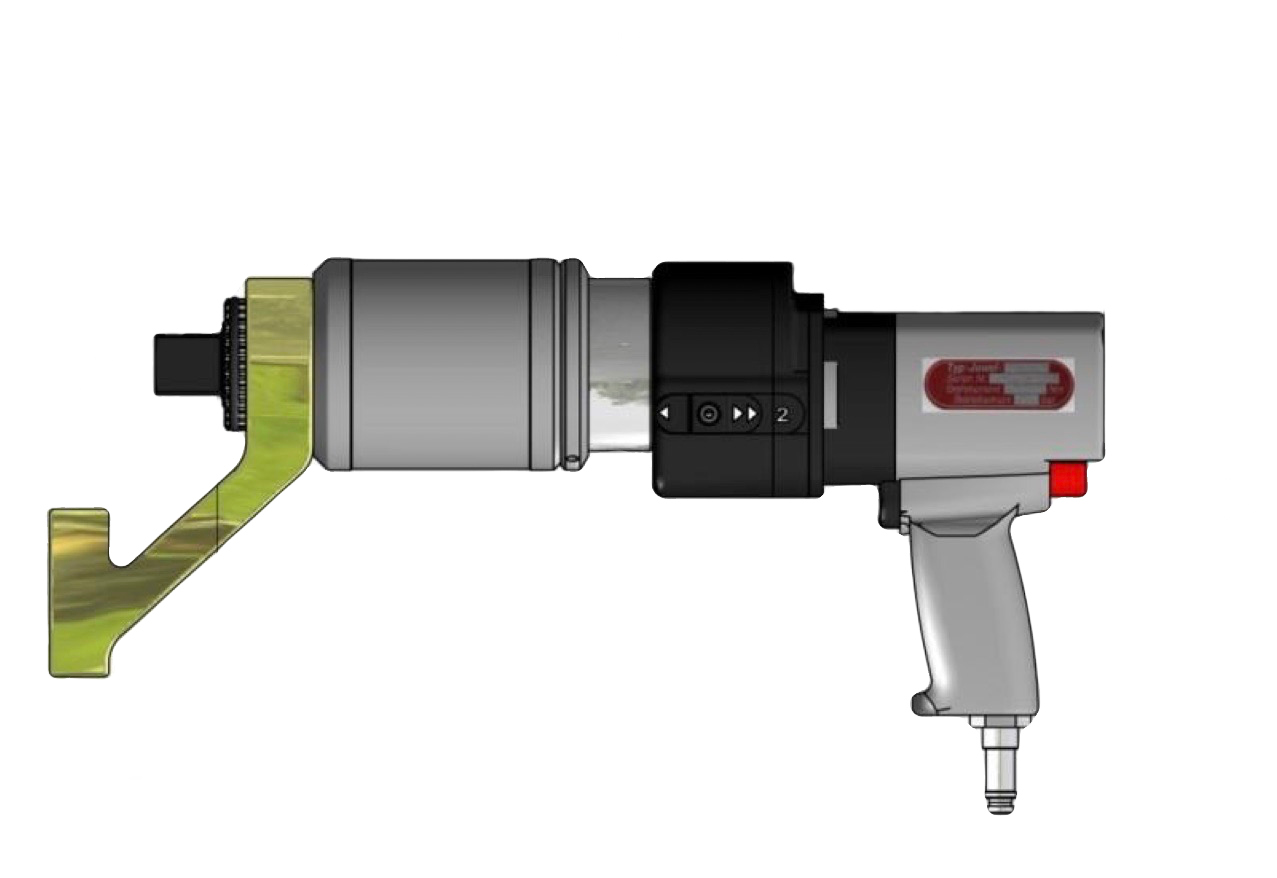

Pneumatic Torque Wrench (PTW)

Key Features:

Technotorc introduces the all new PTW-Series Pneumatic Torque Wrenches. These tough and reliable tools are designed to provide fast, safe, and simple fastening for applications that require controlled bolting solutions.

The Pneumatic Torque Wrench tools are robust enough to withstand tough job site conditions, and are ideal for applications with a high volume of fastenings typically found in the mining, power generation and oil & gas industries. A full range of tools provide up to 8,100 Nm (6,000 ft. lbs.) of torque.

Advantages

Productivity

- High speed continuous rotation – For constant torque output

- Low friction planetary gearbox design – Minimizes wear and extends uptime

- High operating speeds – Far exceed those of hydraulic tools

Safety

- Ergonomic, low vibration design – Reduces fatigue and vibration-related injury risks

- Low noise air motor – Ensures quiet, consistent performance indoors and outdoors

- Controlled bolting – Prevents over-torqueing and protects against critical failure

Simplicity

- Trigger style handle – Simple to operate with easy tightening/loosening switch

- Torque gun stall-out – Prevents over-torqueing at pre-set air input pressure

Convenience

- FRL Option – Available with or without Filter-Regulator-Lubricator

- Standard reaction arm included – Wide range of custom arms & accessories available

- CE declared – Tools come with calibration certificate

Accessories

- Reaction Arms – Access deep sockets and uniquely spaced bolts

- Standard Reaction Arm

- Straight Reaction Arm

- Extended Reaction Arm

- Double Straight Reaction Arm

- Blank Reaction Arm

- Sliding Reaction Arms – Adjustable from 10.2 cm to 30.5 cm (4" to 12") from center of spline

- Nose Extensions – 15, 30 & 45 cm (6”, 12” & 18”) for deep bolt access

- Filter Regulator Lubricator (FRL) – Provides clean, lubricated air and pressure control

Model Specifications:

| MODEL NO. | Min (N.m) | Max (N.m) | S | D (mm) | M (mm) | L (mm) | K (mm) | Weight (Kg) | Speed (rpm) |

|---|---|---|---|---|---|---|---|---|---|

| TPTW-04 | 130 | 450 | 3/4" | 74 | 167 | 297 | 195 | 5.3 | 40 |

| TPTW -09 | 290 | 950 | 3/4" | 78 | 172 | 302 | 195 | 5.4 | 20.5 |

| TPTW -16 | 480 | 1640 | 1" | 78 | 214 | 344 | 195 | 6.9 | 11.5 |

| TPTW -20 | 490 | 2050 | 1" | 78 | 214 | 344 | 195 | 6.9 | 9 |

| TPTW -30 | 810 | 3100 | 1" | 88 | 254 | 384 | 195 | 9.7 | 5.5 |

| TPTW -40 | 1190 | 4300 | 1 1/2" | 99 | 254 | 384 | 195 | 9.7 | 3.8 |

| TPTW -60 | 1100 | 6200 | 1 1/2" | 113 | 283 | 413 | 195 | 15.1 | 2.7 |

| TPTW -80 | 1600 | 8000 | 1 1/2" | 120 | 292 | 422 | 195 | 16.8 | 1.9 |

| TPTW -100 | 3700 | 10600 | 1 1/2" | 128 | 336 | 466 | 195 | 21.6 | 1.4 |

| TPTW -120 | 3900 | 13500 | 1 1/2" | 128 | 336 | 466 | 195 | 21.6 | 1.1 |